Miraculous encounters with natural stones. Stone Customize," a one-of-a-kind ring spun by craftsmen's skills.

We want to deliver the beauty of natural stones as they are, each with its own uniqueness

Since the launch of our brand, we have been creating products with the hope that as many customers as possible will be able to appreciate the beauty of natural stones as they are.

Just as each of us has our own personality, each natural stone is full of individuality. Not only the type of stone, but also the size and shape of the same stone, as well as the expression of inclusions in the stone, are different.

Mass-produced products are required to be finished in the same shape. This also means that there are natural stones that are omitted because of their individuality, despite their beauty.

We wondered if it would be possible to focus on these expressive and unique natural stones, and at the same time, to plan products without loss. This idea led to the creation of the "Stone Customize" content.

The joy and exuberance of choosing in Jaipur, India

Jaipur, where gems from all over the world are collected and distributed, is known as one of the world's leading jewelry cities.

Because of the abundance of precious and semi-precious stones mined in the suburbs, luxurious jewelers who were the purveyors of the Maharajas developed. Today, few stones are produced in the city, but jewelers from all over the world visit the city, seeking jewelry techniques that have been nurtured throughout the city's history.

Our production background also started in this city.

There is a sense of excitement that cannot be found in ready-made jewelry, in the treasure hunt-like sensation of selecting a favorite stone from a wide variety of unique stones, and in facing oneself by trusting one's intuition. The time spent feeling the power of the stones, being enchanted by their pure beauty, and transforming them into jewelry is filled with indescribable joy and pleasure.

We purchase stones for stone customization so that you can experience this feeling as much as possible. We want everyone to experience this uplifting feeling and learn more about the charm of ARTIDA OUD... "Stone Customizing" is the content that makes this desire come true.

Stone Customization" is renewed

This year marks the 5th anniversary of the brand launch. The price of gold continues to soar at a tremendous rate in response to the world's situation. In order to increase the variation of affordable prices, we have made it possible to choose "SILVER925 with K18 coating" as the base metal material. Furthermore, in order to deliver "Stone Customized" products to our customers with more peace of mind, we have reviewed our manufacturing process and have renewed it since last May 2023.

Natural stones that came all the way from the land of Jaipur to a faraway country and were chosen by fate. What kind of process is used to create a setting that perfectly matches the shape of such unique and one-of-a-kind stones?

This time, we closely followed this process, and once again, our interview focused on the high level of skill and attention to detail that only first-rate craftsmen can bring to their work.

How to Order "Stone Customization

First of all, we would like to introduce how to order "Stone Customize".

Select your favorite stone from among more than 30 types of unique stones available at any given time. Once you select a stone, it will be set on the ring on your hand, and you can confirm the size and color of the stone. The orientation of the stone can be changed every 90 degrees on the simulation screen. You can choose between 10k gold and 18k gold, and order sizes from size 3 to 13 in increments of 1.

From order to completion

1. wax molding

We use the latest technology and ingenuity to create a unique piece of jewelry that is not bound by conventional methods.

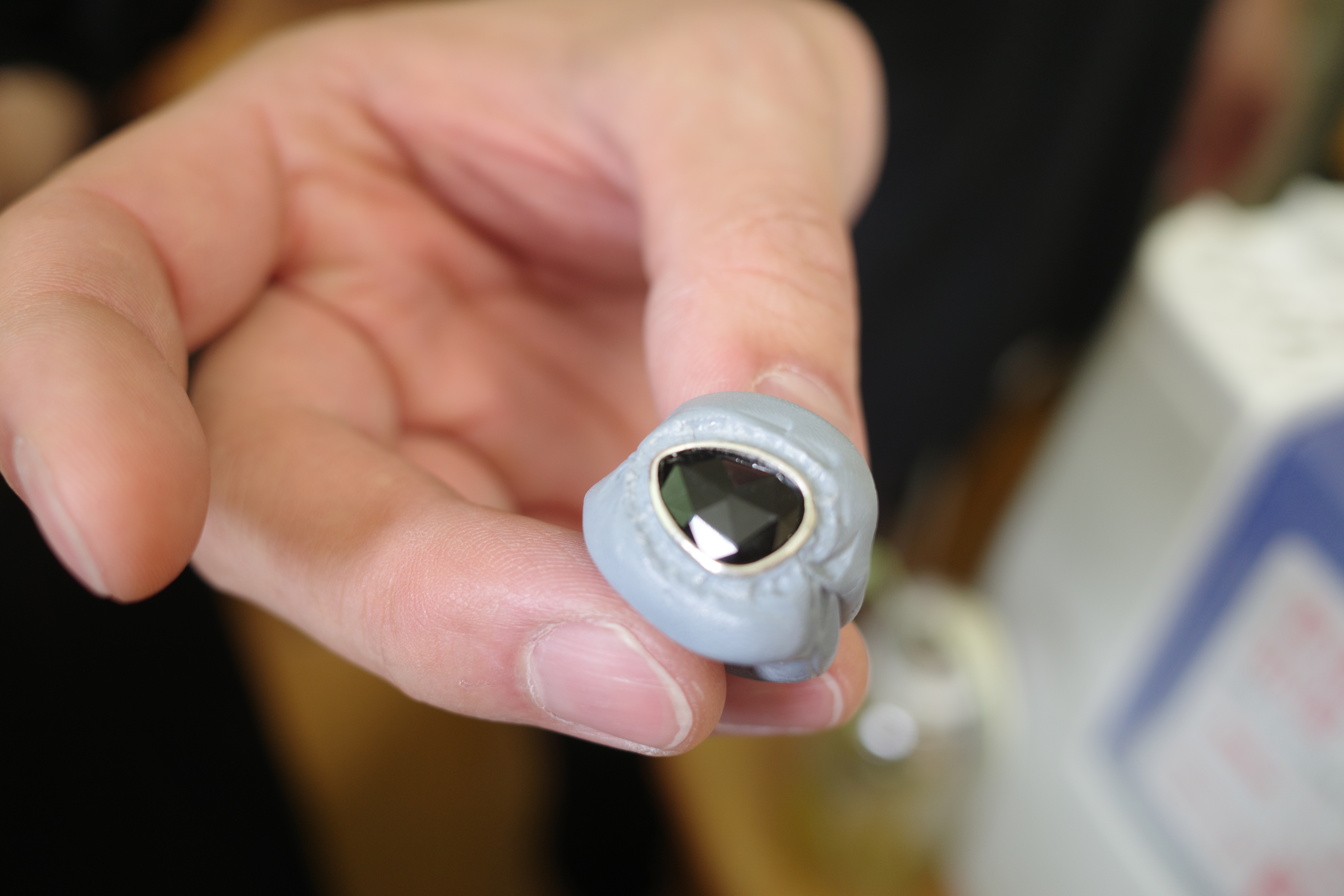

First, we wrap the stone with wax, which can be shaped to fit each stone, and cut off the excess to make a frame. The shape of this frame becomes the metal part that surrounds the stone. This time, the ring was created using a sample of the "black spinel" stone, which is said to enhance one's personality and give one the desire to push forward toward one's goals.

This time, the ring was created using a sample of the "black spinel" stone, which is said to enhance one's personality and give one the desire to push forward toward one's goals.

2. wax tree production and firing (making plaster molds)

-Detailed and artistic assembly and skillful techniques that do not waste metal.

Casting is a manufacturing method in which melted metal is poured into a plaster mold (mold) and cooled to form a ring.

In order to perform this casting process, a "mold," which is a plaster mold, is first needed to make the mold. The process of making the mold is called wax tree production and firing.

Wax tree

A wax tree is a design pattern made of wax and assembled to look like branches on a tree. The wax tree is fixed to a metal mold cylinder and the embedding agent (plaster) is poured into it.

The amount of metal used and the efficiency of the process depend on how many wax patterns can be incorporated in a single casting, which in turn increases the difficulty of this delicate process. The slightest deviation can result in holes or plaster that does not flow properly, so building a tree is a precise craftsmanship and wax tree is truly an art.

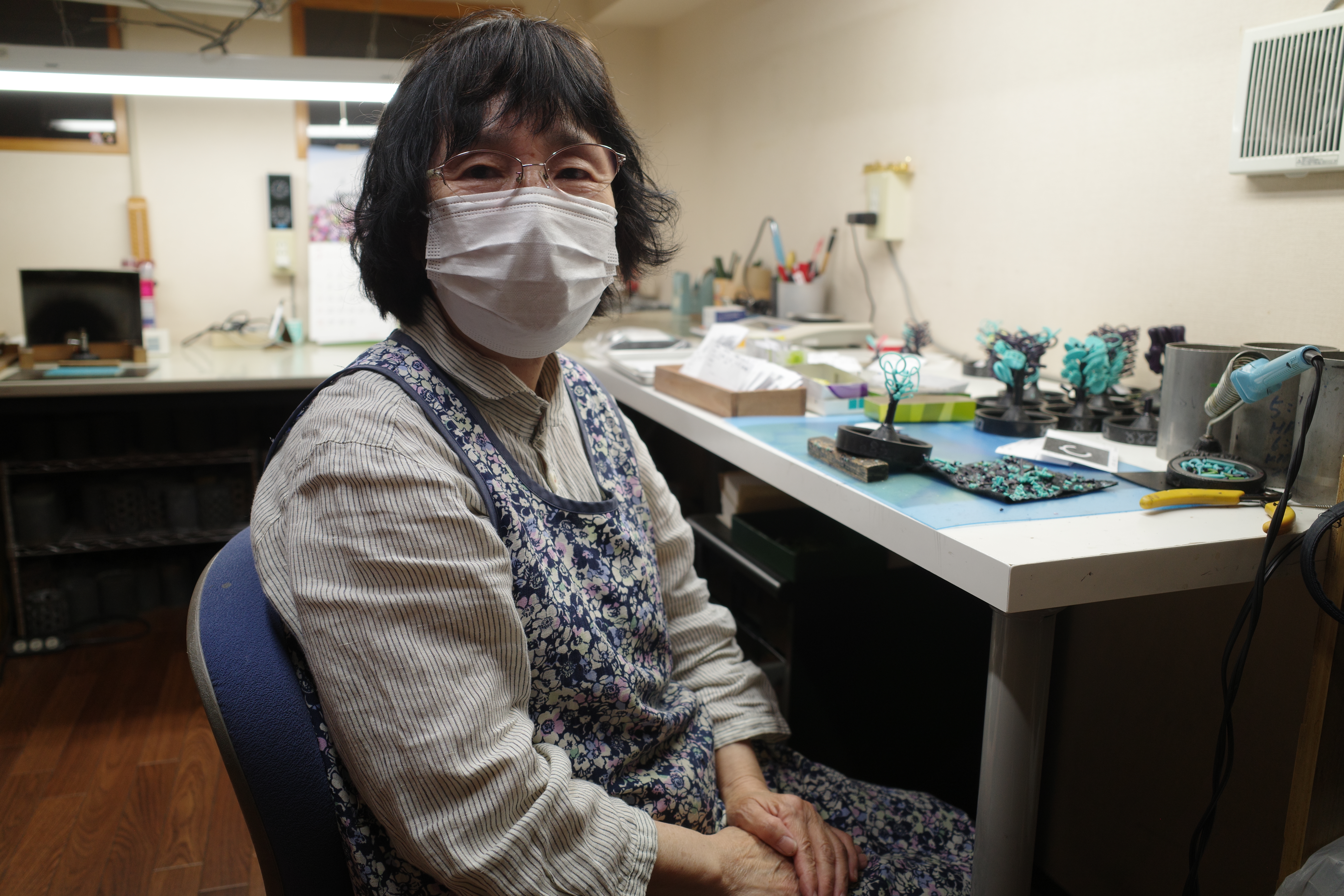

ツリー建ての名人。気さくな人柄の職人、高橋さん。

Firing.

Once the plaster has completely hardened, the cylinder is heated in an electric furnace during the firing process. The high temperature melts the wax and creates a cavity into which metal can be poured, completing the plaster mold (mold).

3. casting

-Casting is an important process in which a metal is finally formed into a metal object by a specialized machine.

In casting, molten metal is poured into the cavity of a plaster mold at high temperature. Pressure is applied to ensure that the metal is poured into every nook and cranny of the mold. The melting temperature of the metal is so high that casting is only possible with specialized equipment. Once the metal has cooled and hardened, it is removed from the casting and finished.

4. finishing

The finishing of each natural stone is the result of the craftsman's experience and intuition, and is unique to each piece of natural stone.

Once the tree has been turned into ingots, the work is passed on to precious metal craftsmen, who then proceed to the stone setting, polishing, and finishing processes.

Stone Matching

After the stone frame is processed, the "stone matching" process is carried out to match the natural stone even more precisely. It is a very important process to ensure that the natural stone sits beautifully on the stone frame in order to perfect the stone clamping process. The stone is shaped to fit the shape of the stone by checking it over and over again with a loupe to ensure that no space is left between the two stones. The stone seat is adjusted to the nearest millimeter.

The stone seat is adjusted to the nearest millimeter. A black spinel sample is "stone matched" to the shape of the stone.

A black spinel sample is "stone matched" to the shape of the stone.

Stone clasp

Ishidome" also plays the role of integrating the design of the stone frame with the stone clasp and making the frame and the gemstone itself look beautiful. The stone is held in place with the fingers so that it does not slip out of place, and then the stone is clamped by placing a hammer on the stone and repeatedly tapping the sides of the stone with a fine hammer.

The stone is held in place by a metal hammer that is tapped repeatedly and finely on the sides to hold it in place. The stone is held in place so that it is slightly covered in accordance with the shape and cut of the stone. The craftsman's experience and senses are used to finish the work, adjusting the amount of force to suit each piece and the tapping force to prevent cracking. This is truly the result of skilled craftsmanship.

Skilled craftsmen work with tools that they have maintained themselves to fit their hands and be easy to use. One of their skills is to use the most appropriate tool for each type of stone or ingot.

Breathtakingly delicate stone clasping work. The hammer was also made by the craftsman, Mr. Sato himself.

The beautiful stone frame is beautifully integrated with the natural stone, which has been completely stoned.

Polishing and Finishing

The inside diameter of the ring and the areas where the stones are tapped are polished, relying on the slight vibrations transmitted by the polisher's fingertips. The smoothness of the metal, the beauty of the surface, and the ease with which the ring passes through the fingers are all determined by the polishing technique of the finisher. Mr. Yoshida is a master polisher and craftsman.

Mr. Yoshida is a master polisher and craftsman. A one-of-a-kind stone customized custom ring completed by a relay of craftsmen's skills.

A one-of-a-kind stone customized custom ring completed by a relay of craftsmen's skills.

The miracle of encountering a single natural stone from among many that have come all the way from faraway India.

The miracle of the encounter of selecting one of the many natural stones that came all the way from India, and the process of sublimation of that one natural stone into jewelry by skilled craftsmen.

We sincerely hope that you will feel the elation and joy of completing your one-of-a-kind ring, and that you will be further enchanted by the story spun in it, and wear it with great care.

Stone Custom ize is here

We conducted an interview at the workshop where "Stone Customize" is made. Please take a look. Click here for the interview