Prayer of the Future

Pray of the Future- Visiting REMARE, a company that takes on the challenge of tackling the marine plastics issue

One of the issues facing the Sea of Ise-Shima is the retention of drifted marine debris due to its complicated deeply indented shoreline.

In fishery industries, such as oysters, seaweed, and pearl farming that are thriving in the region, plastics are used in most of the fishing gear, including buoys, nets, and farming baskets for Akoya pearl oyster cultivation.

REMARE is a company that collects and recycles industrially produced plastics, floating marine plastic debris, and household plastic waste to produce a variety of products.

We interviewed Masasuke Mase, the representative, about why he started this kind of business. Masasuke Mase, representative of REMARE. "My dream is to build an offshore city," he talked about his future prospects.

Masasuke Mase, representative of REMARE. "My dream is to build an offshore city," he talked about his future prospects.

From a navigator to being involved in manufacturing industry, I want to share the power of the sea.

"I used to be a navigator and sail on ships. At that time, I often felt that life at sea was completely different from life on land. On the sea, of course, you can't get anything except what you have brought with you, so you have to make do with what you have,but I think that's the way living is supposed to be", said Mr. Mase and he continued.

"Even if all you have is a pair of scissors, you can turn it into a hammer if you use it to knock. We have to look at tools in an abstract way and use them flexibly. This kind of thinking ability is what the life at sea requires."

While working as a navigator, Mr. Mase was fascinated by the power of the sea. On the other hand, when he returned to land, he found that we were living in a world of mass production and mass consumption, the exact opposite of the life at sea. It also made him question whether the economy was supported by such system.

"While I was thinking about that, I saw a tremendous amount of marine plastic debris floating off the coast of the Philippine Sea. We, the ship's crew, had been melting the scrap iron on board and remolding it into something else, which requires a lot of energy. We once melted down some plastic we had recycled, and it melted at only 140 degrees. At the time, I felt it was really an amazing material! "

The second floor of the factory is a secret base for adults with a bar.

This is how Mr. Mase has made the transition from being a navigator to a recycler of marine plastics debris. After taking on challenges in various places, he finally ended up in this location overlooking the sea in Ise-Shima. This building, which is now the factory, used to be a fish store. He renovated it with his own hands to its current look. The second floor of the factory is a miscellaneous but dreamy space filled with samples and prototypes. You can feel the passion for manufacturing.

The second floor of the factory is a miscellaneous but dreamy space filled with samples and prototypes. You can feel the passion for manufacturing.

"We first created a bar space on the second floor of the factory. People may find it difficult to understand what we do, so we created the bar first as a place to communicate with the fishermen and the local community."

Currently, REMARE has established a collection system for plastic waste generated from the local marine industry. The company recycles up to 100 tons of waste plastic annually and transforms it into new products.

The dream of manufacturing, and the future that lies ahead.

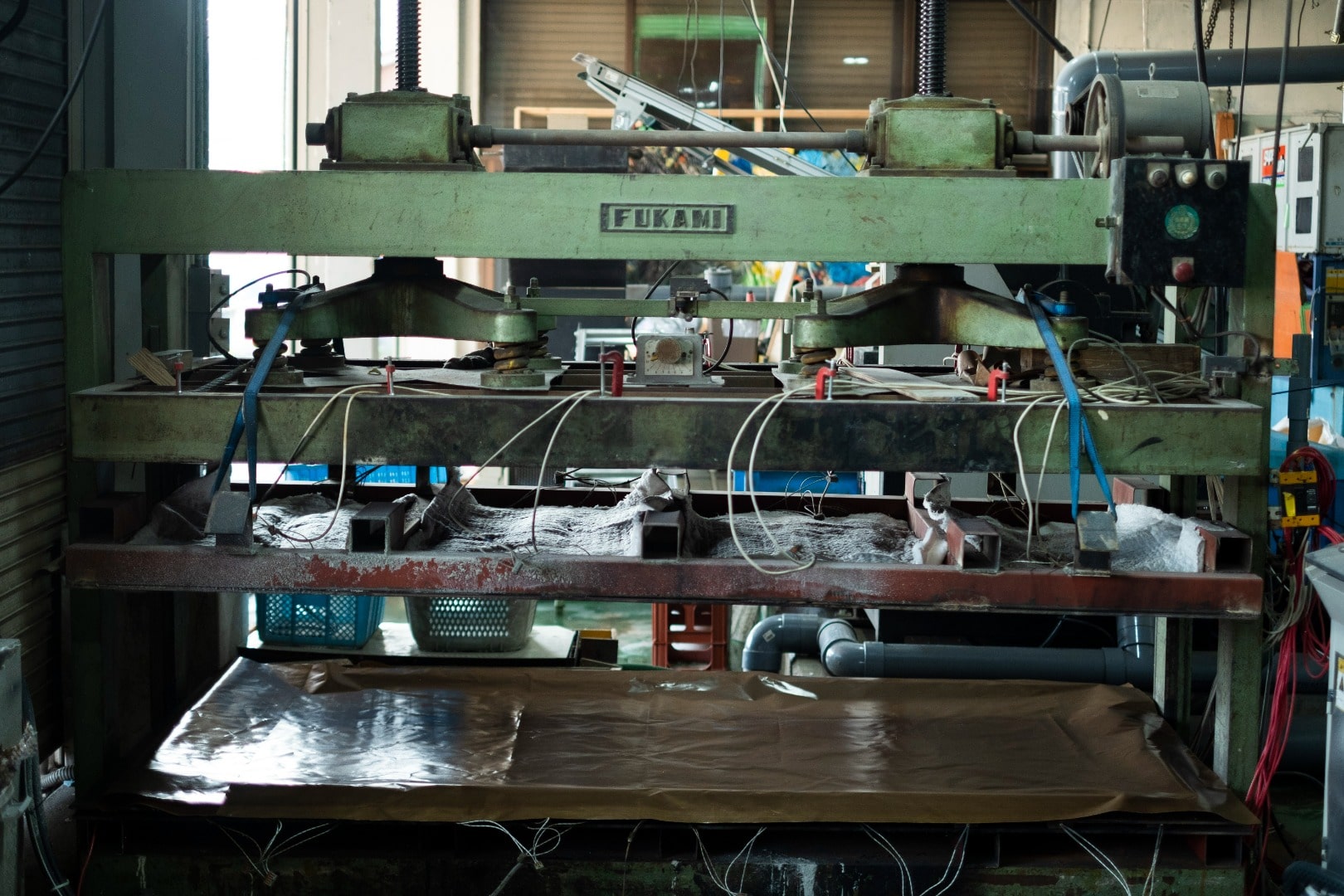

Production is in full swing on the first floor of the factory. Large machine tools were purchased and refurbished for threshing and pressing plywood. The way the machines produce dynamic sound and heat will make you feel being in a world of steampunk. It seems to be the place where dreams of manufacturing are materialized. Press machine for producing plastic boards. Mr. Mase modified the machine for manufacturing plywood with his own hands.

Press machine for producing plastic boards. Mr. Mase modified the machine for manufacturing plywood with his own hands.

Finely crushed waste plastic chips are placed in a press machine, subjected to the pressure with a heat of 180℃, and a plastic board about the size of a tatami mat is completed in a few hours.

The recycled plastic boards produced will be transformed into a variety of products, including building materials. In addition to original products, the company also collaborates with various artists and designers, and is planning to further expand the scale of the factory.

Mr. Mase also conducts beach cleanup activities with local fishermen and children. His desire to "share the power of the sea" is, miraculously being given back to the sea. The plastic that has been beautifully reborn from the waste will brighten our future. Currently, the company is also collecting and recycling plastic bottle caps and other waste from households and commercial facilities.

Currently, the company is also collecting and recycling plastic bottle caps and other waste from households and commercial facilities.

This time, designer Shae Honda created a small amulet "Amulet bag" with the recycled plastic chips produced by REMARE. The chips are printed with the patterns of "Seman" and "Doman", which ama divers paint on their bodies. The amulets are one of its kind due to their unique manufacturing characteristics. Don’t miss the chance to get one at the venue.